Automation and Robotics engineering is a field of engineering that deals with the design and creation of robots.

Automated & Robotics engineers make use of knowledge from computer, mechanical, electrical, biological & software engineering.

Performing research into the design, operation, and performance of robotic mechanism components or systems.

About B.Tech. Robotics and Automation Engineering

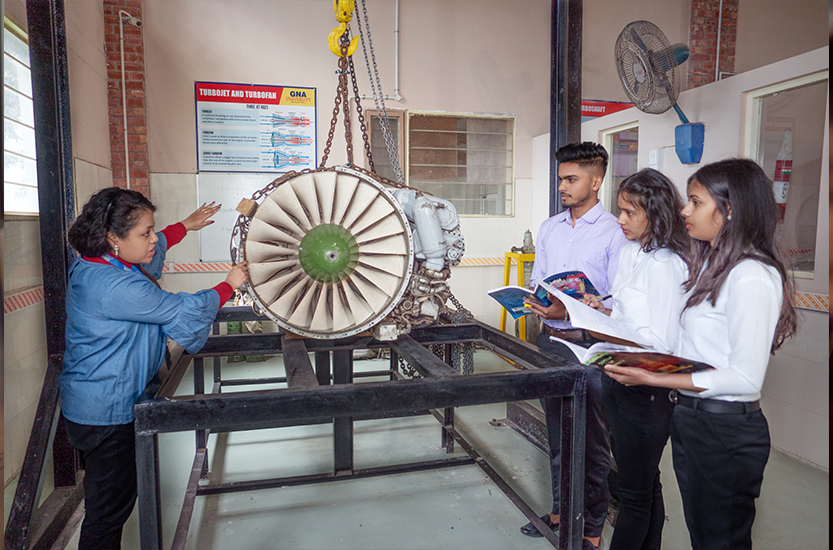

B.Tech in Robotics and Automation Engineering is a four year advanced graduation program that has always been aspiring to generate industry ready engineers in the field of Robotics.

Highly experienced faculty strives hard to build careers in the upcoming technologies which bridges the gap between efficient technologies like robotics, automation and the knowledge required to implement these technologies.

Robotics is a field of engineering that imparts the knowledge for using control systems and information technology to reduce the need for human work.

With the advent of 21st century, the use and functionality of Robotics have gained impetus because of its use in high precision tasks.

Career Pathways

- Design and Development of Robots

- Automation System Engineers and Consultant

- AI and Automotive Industry

- Mining and Ocean exploration

- Robotic Process and Automation Developer

- Aircraft and space Research Industries

- Defensive and Military Companies

- Nano- Technology

Program Outcomes:

Program Specific Outcomes:

Download B.Tech. Robotics and Automation Engineering Brochure

PROGRAM HIGHLIGHTS

- The graduated students of this program can apply their knowledge to anticipate the need of Robotic Manipulators in new sectors and design robots with new applications in industry and also plan the trajectory for various robotic manipulators by using different techniques.

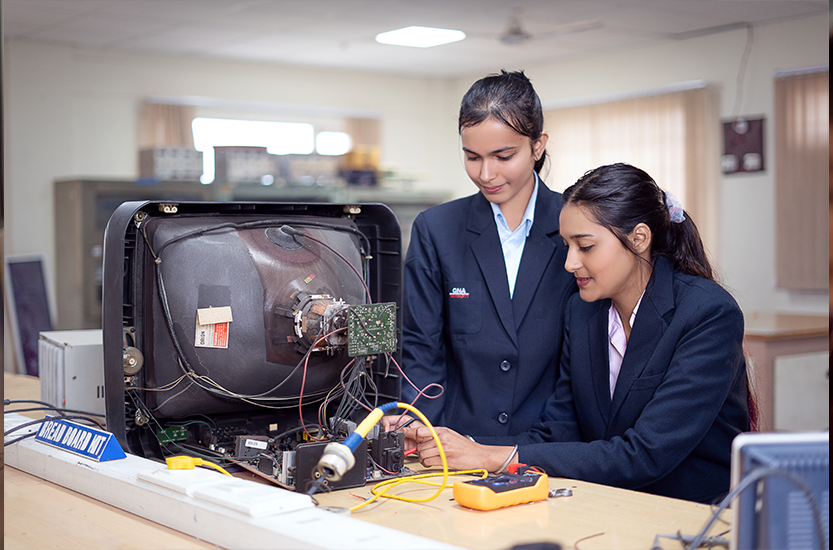

- The students will be able to understand and adapt to the different robotic control environments, robotic vision and various sensing techniques.

- The students can apply the skills to solve complex multi-disciplinary problems, identify the type of robotic manipulator required and to provide a Robotic solution to serve the purpose.

- The knowledge imparted to the students will allow them to practice and implement new ideas for the product design and development and to provide the adequate design and manufacturing solution through the updated CAD/CAM technologies.

SEMESTER WISE SUBJECTS

| Sr. No. | Course Code | Semester | Course Title |

|---|---|---|---|

| 1 | BRE404 | IV | Virtual Reality Systems and Applications |

| 2 | BRE505 | V | Artificial Intelligences in Robotics |

| 3 | BRE603 | VI | Neural Networks and Fuzzy Systems |

| 4 | BRE603 | VII | Advanced PLC and SCADA Programming |

| 5 | BRE803 | VIII | Computer Integrated Manufacturing Systems |

| Sr. No. | Course Code | Semester | Course Title |

|---|---|---|---|

| 1 | BEE302 | III | Digital Electronics |

| 2 | BEE322 | III | Digital Electronics Laboratory |

| 3 | BEE405 | IV | Robotics and Control |

| 4 | BEE427 | IV | Robotics and Control Laboratory |

| 5 | BEE541 | V | Fluid System |

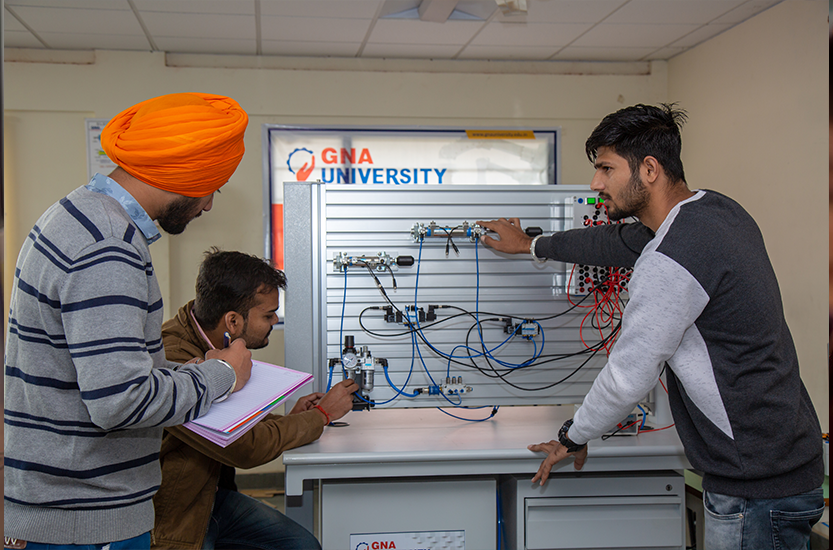

| 6 | BRE525 | V | Fluid System Laboratory |

| 7 | BRE601 | VI | Robot Kinematics and Dynamics |

| 8 | BRE621 | VI | Robot Kinematics and Dynamics Laboratory |

| 9 | BRE702 | VII | Product Lifecycle Management |

| 10 | BRE722 | VII | Product Lifecycle Management Laboratory |

CAREER OPPORTUNITIES

The students after pursuing B. Tech. Robotics and Automation Engineering can design design experimental robotic models, design production line robots with programmable arms, , carry out regular checks on existing robotic models. One can also do specialization in robotic field of study like Automation, Micro-Robotics, Robot Motion Planning, Signal Processing, Robot Manipulators, Artificial Intelligence etc.

A qualified robotic engineer will find increasing employment opportunities in areas like manufacturing industries, agricultural equipment manufacturing firms, mining industry, nuclear power plants, research division of mechanical/electrical engineering firms, sea exploration, space research organizations, biomedical equipment manufacturing firms, gaming industry, to name a few.

You can now find robotic applications in varied fields such as:

- Design and Development of Robots

- Robotic Process and Automation Developer

- Robotic Test Engineers

- Automation System Engineers and consultant.

- AI industry

- Manufacturing industries

- Transportation and logistics

- Defense and military companies

- Aerospace and space research industries

- Mining

- Ocean exploration

- Nano-technology

- Surgery

- Modern warfare

- Space-exploration

PLACEMENTS

Prospective Government & Private Sector Companies where design graduates can work after completion of Bachelor of Design Automotive & Product Design Program